Nationwide Inventory of Intangible Cultural Heritage

Watchmaking

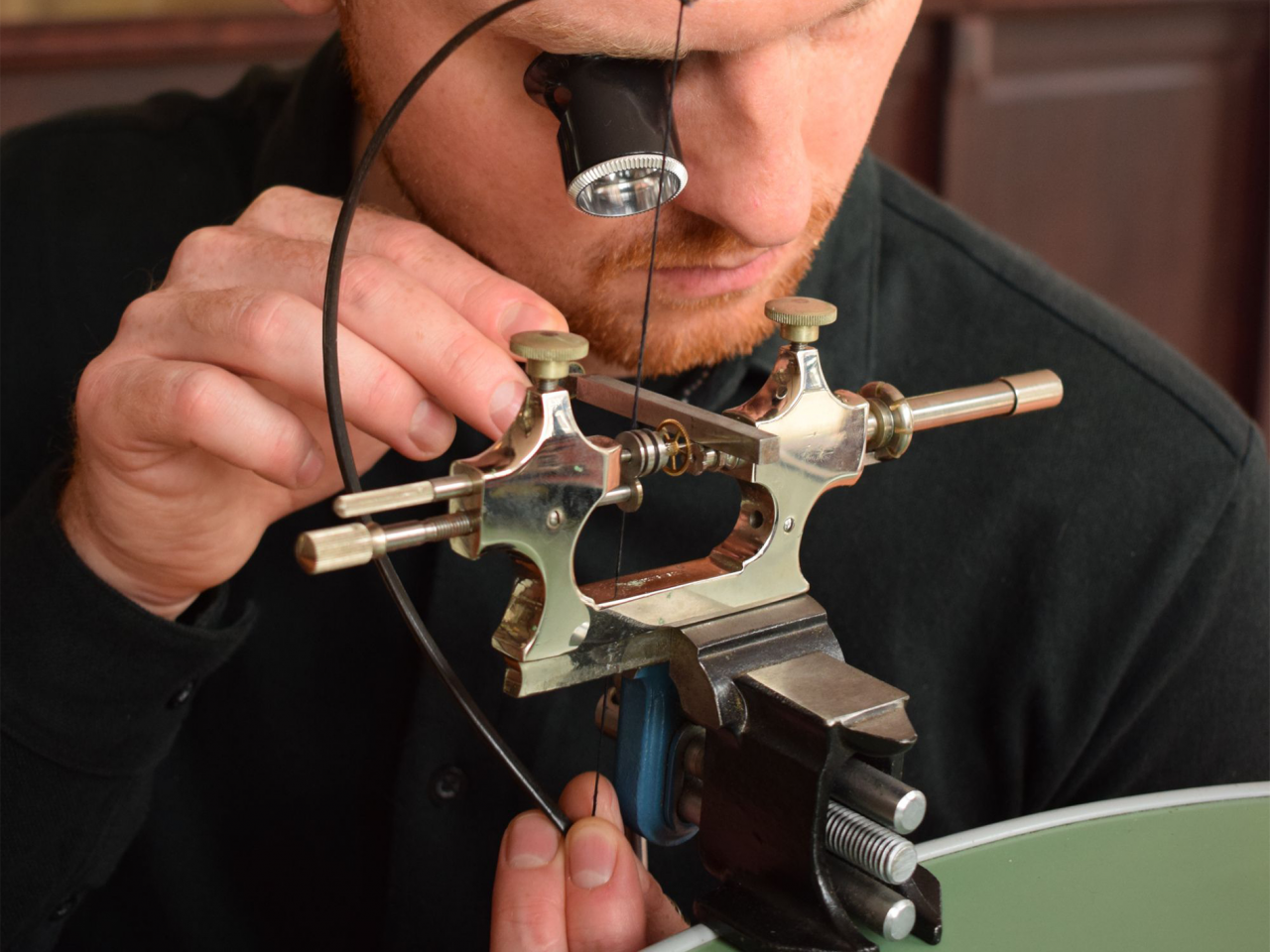

Watchmaking requires a broad knowledge of everything from historical to electronic timepieces. Passing on theoretical knowledge, diverse craft techniques, and restoration and maintenance skills maintains the vitality of the watchmaking craft.

There are currently around 2,600 craft businesses nationwide. Timekeeping as the basis of watchmaking has helped shape historical developments such as lake navigation and industrialization.

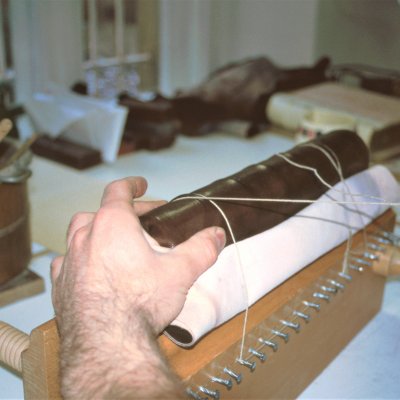

In addition to traditional metalworking techniques, watchmakers used to have to learn how to calculate gears and make wheels and pinions. A special art was to make the escapement system. Soon the watches were equipped with additional systems: chiming movements and complicated displays showing planetary movements, moon phases or the date. The invention of the mainspring in the 1500s made it possible to manufacture small portable watches. The basic craft skills have changed little since then.

Today's watchmaking training is still largely based on the traditional knowledge and skills of materials such as iron, steel or brass, their processing and the techniques of sawing, filing, drilling, turning, grinding and polishing. Modern manufacturing technologies have been added, while the tools have hardly changed over the centuries.

New techniques in watchmaking

While watchmaking used to be based purely on mechanical timekeeping, since the development of electrical engineering and electromechanics, the knowledge and understanding of electrically driven watches as well as quartz and radio-controlled watches have also been part of the profession. In Germany, this knowledge is conveyed by training companies and vocational schools.